About Us

About Us

SURE SAFETY

Uplifting Industrial Safety for Greater Profitability and Advancement.

Introduction to

Sure Safety and its Mission

Welcome to Sure Safety, a pioneering force that reshapes industrial safety into a strategic tool for enhanced productivity and profitability. Founded in 2004 by Mr. Nishith Dand, our journey started with a visionary insight: transforming safety measures from a mere obligation to a dynamic driver of revenue.

Our commitment extends beyond shielding lives; we empower businesses with comprehensive safety solutions that resonate with growth and prosperity.

Mr. Nishit Dand

Founder & Managing Director

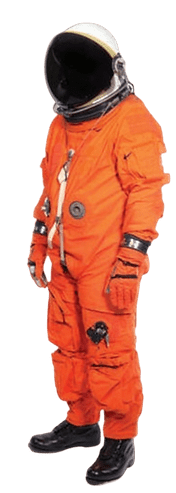

Makers of India's 1st Engineering model of the astronaut crew escape suit commonly known as

"The Space Suit"

Empowering India &

Achieving New Heights

At Sure Safety, we recognize the intrinsic value of safety in every workplace. Our mission aligns with India’s progress, addressing the critical need for advanced safety solutions across diverse industries.

By fostering safety awareness and delivering impeccable safety gear, we contribute to the well-being of workers and the growth of enterprises. Notably, our pivotal achievement of designing India’s inaugural Space Suit for ISRO in 2015 not only symbolized technological prowess but also positioned us as global leaders.

Unveiling the Unrivaled Advantages

USPs Of Sure Safety

Sure Safety’s unrivaled USPs propel us to the forefront of industrial safety transformation:

Corportae Social Responsibility (CSR)

Beyond business, we are ambassadors of positive change. Our CSR initiatives propagate safety consciousness beyond corporate boundaries, influencing local communities and instilling a culture of safety from the ground up.

State-of-the-art Manufacturing Unit

Safety starts with quality. Our state-of-the-art manufacturing facility produces 1,00,000 safety garments and helmets annually. This in-house strength ensures precise control over quality, ensuring each product safeguards lives effectively.

Cutting-edge R&d Facility

Innovation fuels our DNA. Our dedicated R&D facility propels us into the future of safety solutions. With in-depth industry insights and hands-on experience, we pioneer tailor-made safety solutions that define industry standards.

Expansive Global Market Reach

Safety knows no borders, and neither do we. Our influence stretches across India and 20+ global regions. Our understanding of regional safety nuances makes us the trusted partner of industries ranging from Petroleum to Engineering.

Empowering Human Resources

Our team isn’t just skilled; it’s a symphony of expertise. Industrial Hygiene, Safety, Medicine, Technology, and Marketing converge seamlessly in our team, ensuring holistic project execution across the safety spectrum.

Holistic Consultative Process

Our team isn’t just proficient; it’s an orchestra of expertise. Industrial Hygiene, Safety, Medicine, Technology, and Marketing harmonize seamlessly within our team, ensuring comprehensive project execution across the safety spectrum.

Our Certifications

Approvals & Accredations